Ultimate Guide to Power Cable Selection: Manufacturers Reveal 5 Core Parameters & National Standards

2025-08-20

Selecting the right power cable is more than picking something that "just works." A wrong choice of cable can lead to numerous problems, including overheating, power loss, or even safety hazards. The manufacturer stresses that every cable must be selected based on technical needs, safety requirements, and national standards. This guide will walk you through the five core parameters you must know and the key standards that ensure safety and quality.

1. Voltage Rating

Voltage rating is the maximum voltage a cable can handle without failing. Seems obvious, but you would be surprised how often it's ignored.

Here's the basic range:

- Low Voltage (LV): up to 1 kV, perfect for homes and small offices.

- Medium Voltage (MV): 1–35 kV, used in factories and shopping malls.

- High Voltage (HV): above 35 kV, for transmitting power across long distances.

Go over the rated voltage, and you are cooking the cable from the inside out. Once the insulation breaks down, the game is over and that can happen faster than you think if you're running heavy machinery.

![Ultimate Guide to Power Cable Selection: Manufacturers Reveal 5 Core Parameters & National Standards 1]()

![Ultimate Guide to Power Cable Selection: Manufacturers Reveal 5 Core Parameters & National Standards 2]()

2. Current Carrying Capacity (Ampacity)

If voltage is about limits, ampacity is about stamina. It's the amount of current a cable can carry without overheating. And yes it's not just about the size of the wire, though that's a big part of it.

Ampacity depends on:

- Conductor material (copper beats aluminum in conductivity).

- Cross-sectional area (thicker wires carry more current).

- Installation conditions (bundled cables in a hot space lose capacity fast).

A manufacturer once told me, "Think of ampacity like a water pipe. You can push more water through a bigger pipe, but if it's clogged or hot, flow slows down." Same with cables, heat is the enemy.

3. Conductor Material (Copper or Aluminum?)

This debate has been around for decades. Copper is the gold standard (no pun intended) for conductivity, flexibility, and lifespan. Aluminum is lighter and cheaper but needs a bigger size to carry the same current.

Mixing the two? Possible, but tricky. The different expansion rates can loosen connections over time if not handled with the right fittings. Some older installations have failed simply because this detail was overlooked.

4. Insulation Type

Insulation is not just a coating, it is what stands between you and a dangerous live wire.

- PVC: Budget-friendly, flame-retardant, common in household wiring.

- XLPE: Handles higher temperatures, great for underground runs.

- Rubber: Flexible and durable, often used in mining or chemical plants.

Ask yourself: Will this cable be underground? In a factory? In the sun? Insulation is where you tailor the choice to the environment.

5. Installation Environment

Even the best cable fails if used in the wrong place. Outdoor cables need UV resistance. Underground ones need moisture barriers. In industrial zones, you might need electromagnetic shielding.

One example: a textile mill had to replace hundreds of meters of cable because it didn't consider chemical vapors. The insulation broke down in under a year. That's an expensive oversight.

![Ultimate Guide to Power Cable Selection: Manufacturers Reveal 5 Core Parameters & National Standards 3]()

![Ultimate Guide to Power Cable Selection: Manufacturers Reveal 5 Core Parameters & National Standards 4]()

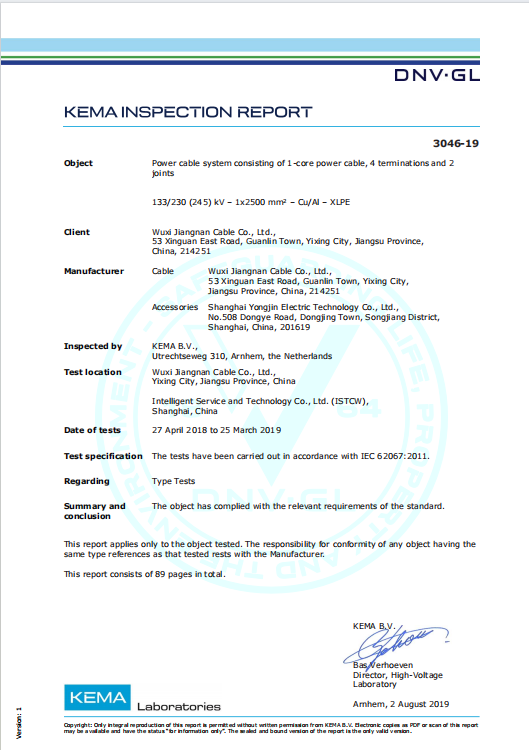

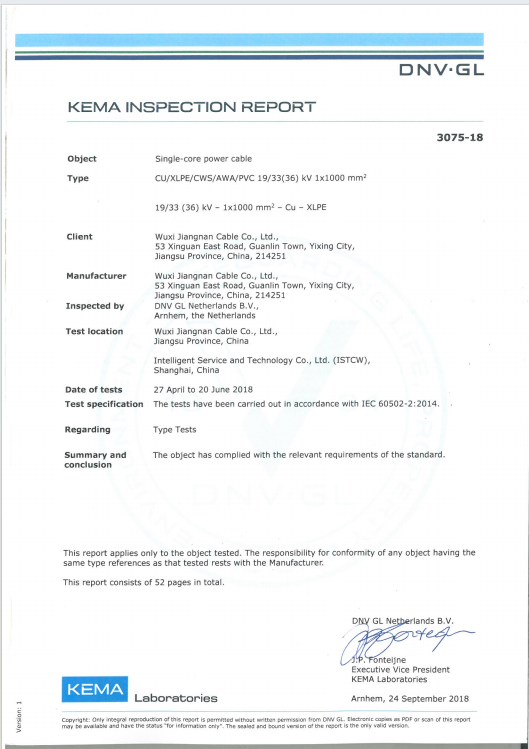

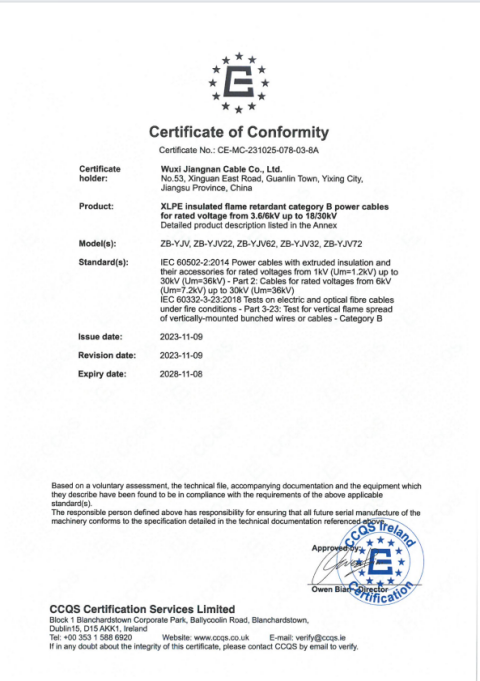

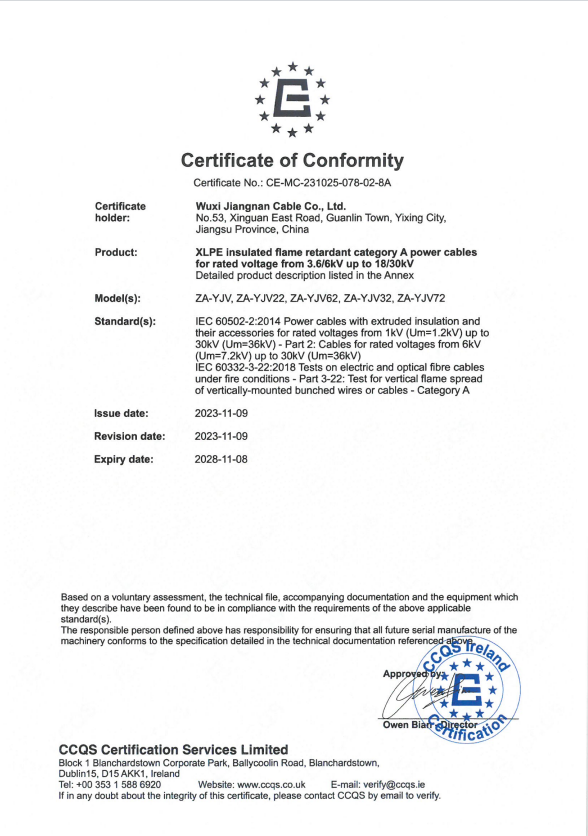

National Standards: Why They Matter?

It's not just about performance, it's about compliance. Every country has its own rules, and using uncertified cables can get you in legal (and insurance) trouble.

Some key standards:

IEC: International benchmark for electrical safety.

BS: British Standards, still widely respected worldwide.

UL: Common in the US and Canada.

GB: China's official standards.

BS: British Standards, still widely respected worldwide.

UL: Common in the US and Canada.

GB: China's official standards.

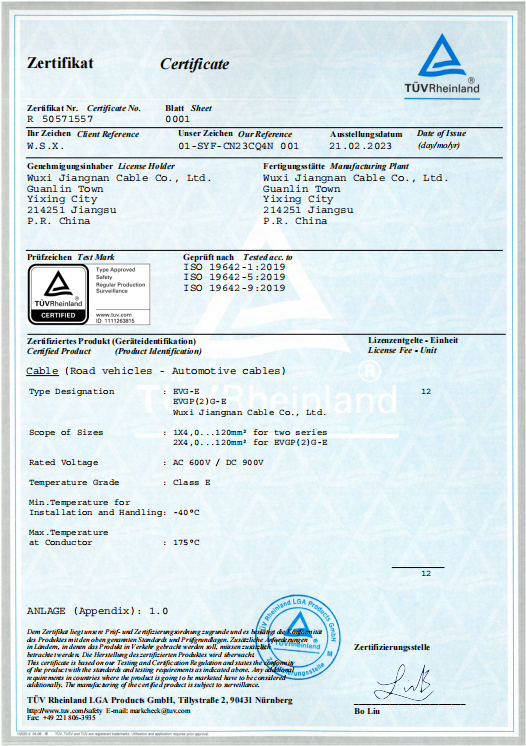

Look for certification marks on the cable or packaging. No mark? That's a red flag.

Pro Tips from the Field

1. Always size cables based on both voltage and current - not just one.

2. Keep an eye on ambient temperature, it can change ampacity dramatically.

3. If you might expand the system later, oversize slightly now.

4. Buy from suppliers with verifiable test reports - not just a verbal, it's good quality.

5. Don't cut costs on connectors, bad joints ruin even the best cables.

2. Keep an eye on ambient temperature, it can change ampacity dramatically.

3. If you might expand the system later, oversize slightly now.

4. Buy from suppliers with verifiable test reports - not just a verbal, it's good quality.

5. Don't cut costs on connectors, bad joints ruin even the best cables.

Why This Matters

Bad cables are a silent problem. They don't usually fail overnight, they degrade slowly, wasting power and quietly raising your risk of fire. The right cable, on the other hand, will do its job for decades with little fuss.

And here's the bottom line: selecting cables is about balancing technical specs with real-world conditions. The five parameters give you the framework, and the national standards make sure you stay on the safe side.

Get both right, and you won't have to think about your cables again, which is exactly how it should be.

recommended for you

no data

Get in touch with us

We are a National Key High and New Tech Enterprise specialized in production, sales and research on wires and cables.

Contact person: Avery Yuan

Contact number: 86-17368469025

Email: avery@jncable.com.cn

WhatsApp: 86-17368469025

Contact person: Mandy Li

Contact number: 86-17368476738

Email: mandy@jncable.com.cn

WhatsApp: 86-17368476738

Copyright © 2025 Jiangnan Cable | Sitemap