Rated voltage 450/750V and below rubber insulated cable (wire)

The product is manufactured according to the standards 《Rubber insulated cable of rated voltage up to and including 450/750V》 of JB/T 8735-2016 《rubber insulated cords and flexible cables of rated voltages up to and including 450/750V》of JB/T 8735-2016, and Q/320282 GAD008-2018, and the same time is also manufactured according to the standard of IEC English gerrymander America.

● Applications

Rubber insulated wires and cables of suitable for power device with moving installation and rated voltage up and including 450/750V

● Fire performance

The fire resistance of the cable is in accordance with IEC 60332-1-2 or IEC 60332-3-22.

Fire resistance of cables in accordance with IEC 60331-21.

Fire non-propagation according to IEC 60332-3-22. LSHF (Low Smoke Halogen Free) according to IEC 60754-1. Low smoke emission according to IEC 61034: light transmittance > 60%. Low corrosive gases emission according to IEC 60754-2.

● Mechanical properties

The minimum bending radius of single-core cables is 12 times the outer diameter of the cable.

The minimum bending radius of a 3-core cable is 9 times the outer diameter of the cable.

● Insulation

Cross-linked polyethylene, type HF XLPE 90ºC, Conforms to IEC 60092-353.

● Outer sheath

LSHF polyolefin outer sheath type SHF1 according to IEC 60092-360. Black color.

General Introduction to Photovoltaic Cables

Welding cable is a crucial connection component in welding operation, it undertakes the important task of transmitting current and signal between welding power source, welding gun and welding parts.

The core of a welded cable is a conductor. It is usually made of multiple strands of fine copper wire twisted to ensure good electrical conductivity and flexibility. This structure can effectively reduce the resistance, so that the current can pass smoothly, and provide stable electric energy for the welding process.

Outside the conductor, there is an insulating layer that plays an insulating protective role. High quality insulation materials have excellent insulation properties to prevent dangerous situations such as current leakage and short circuit. At the same time, it also needs to have high temperature resistance, wear resistance and other characteristics to adapt to the complex and changeable environment of the welding site. Common insulating materials are rubber, plastic, etc., which can maintain the reliability of the insulation effect under high temperature, wear and other conditions.

The outer sheath is also an important part of the welded cable. The sheath not only further protects the insulation and conductors, but also enhances the mechanical strength and corrosion resistance of the cable. It is usually made of materials with good properties such as wear resistance and acid and alkali resistance, so that the cable can be used stably in harsh working environments for a long time.

The performance of the welded cable has a direct influence on the welding work. Its electrical conductivity determines the stability and strength of the welding current, and good electrical conductivity cables can ensure the efficient welding process and obtain high-quality welds. The flexibility allows the cable to flexibly adapt to different welding positions and angles for easy operation by the welder. In addition, the heat resistance of the cable is also very critical, because high temperatures will be generated during the welding process, and good heat resistance cables can maintain stable performance in high temperature environments.

According to different welding processes and needs, welding cables have a variety of specifications to choose from. For example, for high-current welding operations, it is necessary to select a cable with a larger cross-sectional area to carry a larger current; For some cases of fine welding or space limitation, thinner and softer cables may be required.

If you are looking for a marine cable supplier, Jiangnan Cable is your best choice as a top power cable/specialty cable manufacturer in China.

| T ype | Name |

| YQ,YQW | Light flexible rubber cable |

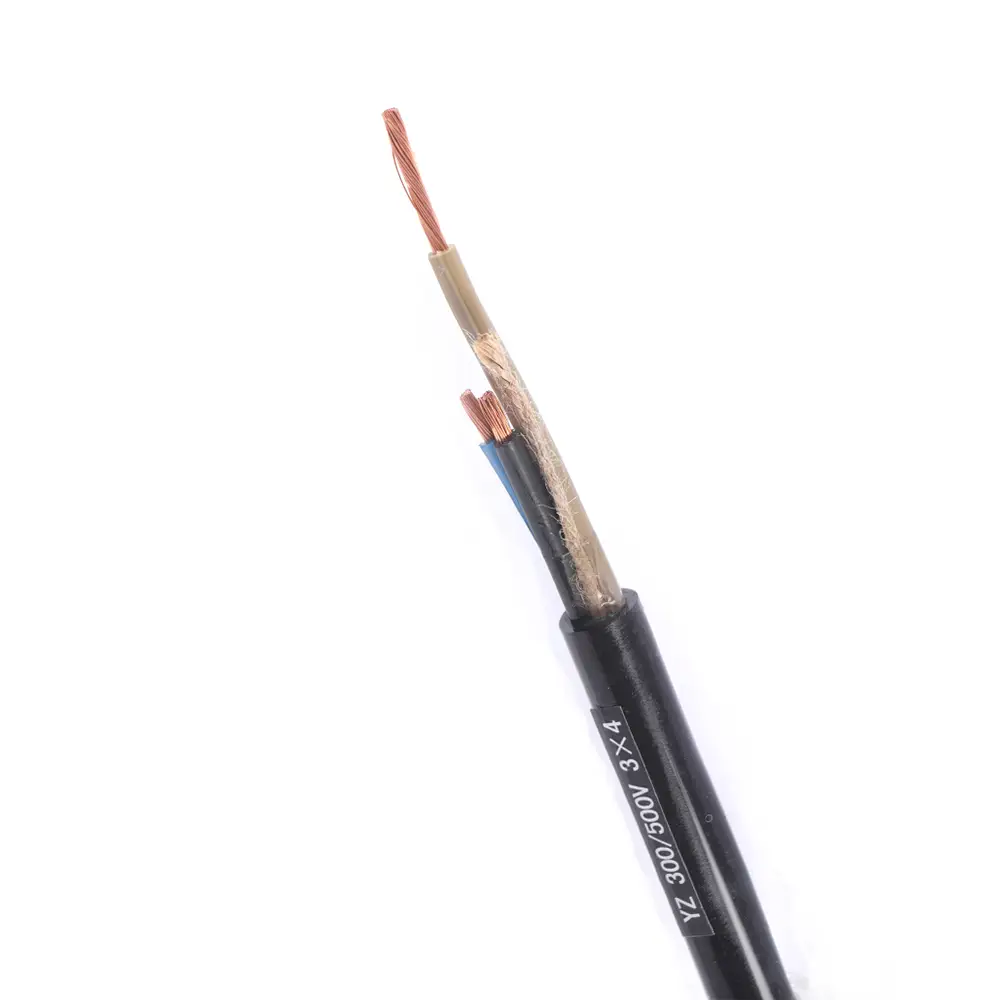

| YZ 60245 IEC 53(YZ) | Medium flexible rubber cable General flexible rubber cable |

| YZW 60245 IEC 57(YZW) | CR or other equivalent synthetic elastomer rubber cable |

| YC | Heavy flexible rubber cable |

| YCW 60245 IEC 66(YCW) | Heavy CR or other equivalent synthetic elastomer rubber cable |

| YZB、YZWB | Medium flexible rubber-sheathed flat cable |

| 60245 IEC 81(YH) | Rubber-sheathed welding cable |

| 60245 IEC 82(YHF) | CR or other equivalent synthetic elastomer rubber-sheathed welding cable |

Good reasons for working with us

● Max. Admissible operating temperature of the conductor: 60℃

● Permissible long-term operating temperature: lowest working temperature is -35℃60245IEC57(YZW)、60245IEC66(YCW)、60245IEC 82(YHF)

● Cables can be used at places contaminated by mineral oil and fuel oil. the bending radius of cables

● Ds25mm:>4D

● D>25mm: ≥6D

● D-Diameter of the cable

● Fire resistance of cables in accordance with IEC 60331-21.

● Fire non-propagation according to IEC 60332-3-22. LSHF (Low Smoke Halogen Free) according to IEC 60754-1. Low smoke emission according to IEC 61034: light transmittance > 60%. Low corrosive gases emission according to IEC 60754-2.

Product display

Product certificate

| Nom cross sectional area mm² |

Insulation thickness mm |

Sheath thickness mm |

Average diameter | Calculated weight Kg/km |

Max.D.C.resistance(20℃) Ω/km |

|||

| Min. mm |

Max. mm |

YQ | YQW | Plain | Metal-coated | |||

| 2×0.3 | 0.5 | 0.7 | 4.6 | 6.6 | 41 | 43 | 69.2 | 71.2 |

| 2×0.5 | 0.5 | 0.7 | 5.0 | 7.2 | 50 | 52 | 39.0 | 40.1 |

| 3×0.3 | 0.5 | 0.7 | 4.8 | 7.0 | 50 | 52 | 69.2 | 71.2 |

| 3×0.5 | 0.5 | 0.7 | 5.2 | 7.6 | 65 | 67 | 39.0 | 40.1 |

| 4×0.3 | 0.5 | 0.8 | 5.0 | 7.5 | 62 | 65 | 69.2 | 71.2 |

| 4×0.5 | 0.5 | 0.8 | 5.6 | 8.5 | 77 | 80 | 39.0 | 40.1 |

| 5×0.3 | 0.5 | 0.8 | 5.3 | 8.0 | 72 | 75 | 69.2 | 71.2 |

| 5×0.5 | 0.5 | 0.8 | 5.8 | 8.9 | 94 | 97 | 39.0 | 40.1 |