Best Brand for Electrical Wires Company

Product Overview

This product is a photovoltaic cable, which is a crucial connection component in welding operations. It transmits current and signal between welding power source, welding gun, and welding parts.

Product Features

The core of the cable is made of multiple strands of fine copper wire twisted to ensure good electrical conductivity and flexibility. It also has an insulating layer with excellent insulation properties and high temperature resistance. Additionally, the outer sheath of the cable enhances mechanical strength and corrosion resistance.

Product Value

The product is professionally tested by a QC team and authoritative third parties to ensure high quality and reliability. Continuous innovation is also a focus, providing better photovoltaic cables to customers.

Product Advantages

The product's professionalism is a key advantage. The cable effectively reduces resistance, allows current to pass smoothly, and provides stable electric energy for welding processes. Its high-quality insulation, temperature resistance, and wear resistance prevent dangerous situations like current leakage and short circuits.

Application Scenarios

This photovoltaic cable can be used in welding operations, providing a reliable and stable connection for transmitting current and signal between welding components. It is designed to adapt to complex and harsh working environments, ensuring long-term stability and performance.

| T ype | Name |

| YQ,YQW | Light flexible rubber cable |

| YZ 60245 IEC 53(YZ) | Medium flexible rubber cable General flexible rubber cable |

| YZW 60245 IEC 57(YZW) | CR or other equivalent synthetic elastomer rubber cable |

| YC | Heavy flexible rubber cable |

| YCW 60245 IEC 66(YCW) | Heavy CR or other equivalent synthetic elastomer rubber cable |

| YZB、YZWB | Medium flexible rubber-sheathed flat cable |

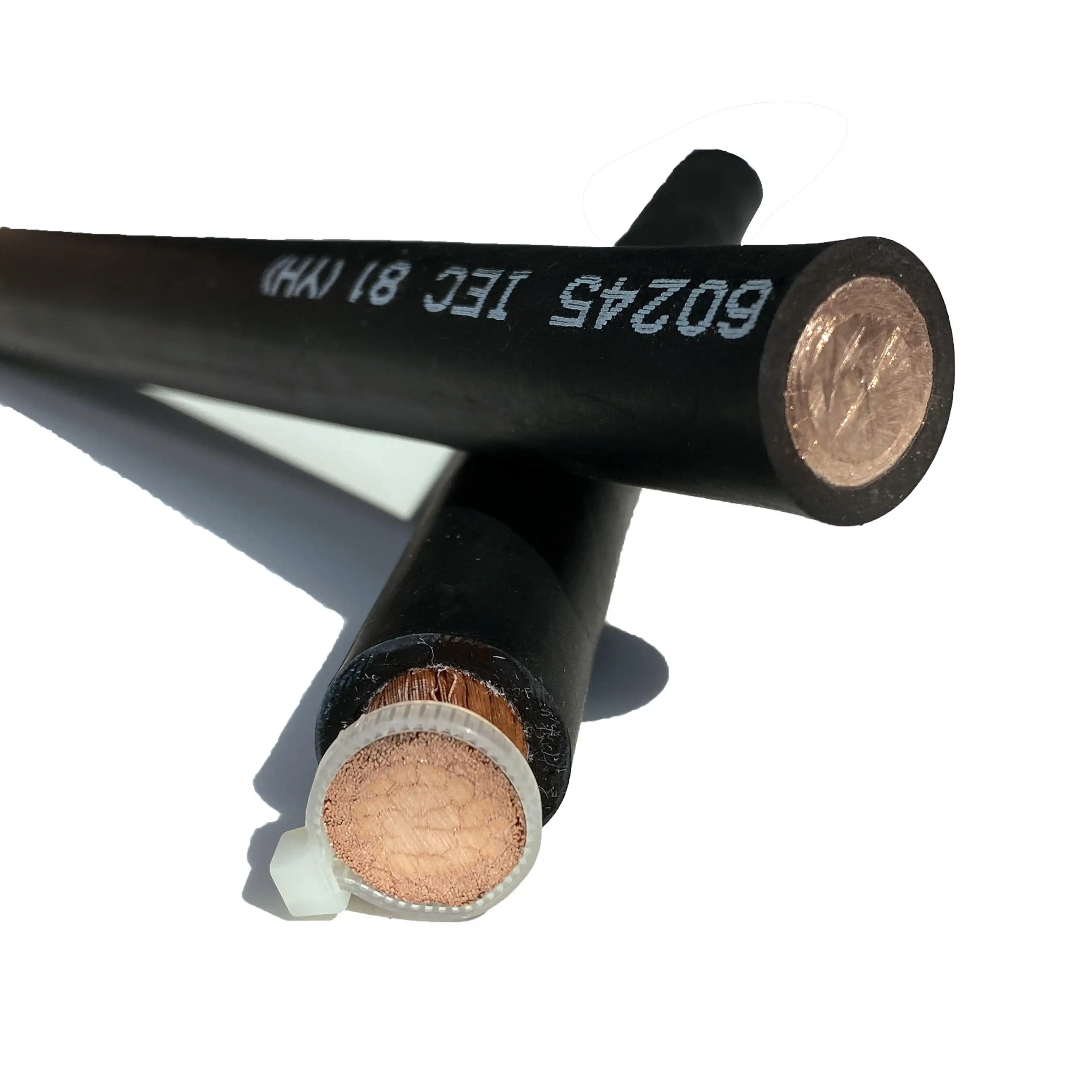

| 60245 IEC 81(YH) | Rubber-sheathed welding cable |

| 60245 IEC 82(YHF) | CR or other equivalent synthetic elastomer rubber-sheathed welding cable |

Good reasons for working with us

● Max. Admissible operating temperature of the conductor: 60℃

● Permissible long-term operating temperature: lowest working temperature is -35℃60245IEC57(YZW)、60245IEC66(YCW)、60245IEC 82(YHF)

● Cables can be used at places contaminated by mineral oil and fuel oil. the bending radius of cables

● Ds25mm:>4D

● D>25mm: ≥6D

● D-Diameter of the cable

● Fire resistance of cables in accordance with IEC 60331-21.

● Fire non-propagation according to IEC 60332-3-22. LSHF (Low Smoke Halogen Free) according to IEC 60754-1. Low smoke emission according to IEC 61034: light transmittance > 60%. Low corrosive gases emission according to IEC 60754-2.

Product display

Product certificate

| Nom cross sectional area mm² |

Insulation thickness mm |

Sheath thickness mm |

Average diameter | Calculated weight Kg/km |

Max.D.C.resistance(20℃) Ω/km |

|||

| Min. mm |

Max. mm |

YQ | YQW | Plain | Metal-coated | |||

| 2×0.3 | 0.5 | 0.7 | 4.6 | 6.6 | 41 | 43 | 69.2 | 71.2 |

| 2×0.5 | 0.5 | 0.7 | 5.0 | 7.2 | 50 | 52 | 39.0 | 40.1 |

| 3×0.3 | 0.5 | 0.7 | 4.8 | 7.0 | 50 | 52 | 69.2 | 71.2 |

| 3×0.5 | 0.5 | 0.7 | 5.2 | 7.6 | 65 | 67 | 39.0 | 40.1 |

| 4×0.3 | 0.5 | 0.8 | 5.0 | 7.5 | 62 | 65 | 69.2 | 71.2 |

| 4×0.5 | 0.5 | 0.8 | 5.6 | 8.5 | 77 | 80 | 39.0 | 40.1 |

| 5×0.3 | 0.5 | 0.8 | 5.3 | 8.0 | 72 | 75 | 69.2 | 71.2 |

| 5×0.5 | 0.5 | 0.8 | 5.8 | 8.9 | 94 | 97 | 39.0 | 40.1 |