The Importance Of Insulation In Cable Technology

Welcome to a deep dive into the critical role of insulation in cable technology. In this article, we will explore why insulation is a fundamental aspect of cable design and how it impacts the performance and safety of various applications. Whether you are a professional in the industry or simply curious about this essential component of cable technology, our insights will provide valuable knowledge and understanding. Join us as we unravel the importance of insulation in cable technology and its far-reaching implications.

Understanding the Role of Insulation in Cable Technology

Insulation plays a crucial role in cable technology, as it is essential for maintaining the integrity and performance of the cables. In this article, we will delve into the importance of insulation in cable technology, examining its function, types, and the impact it has on the overall performance of cables.

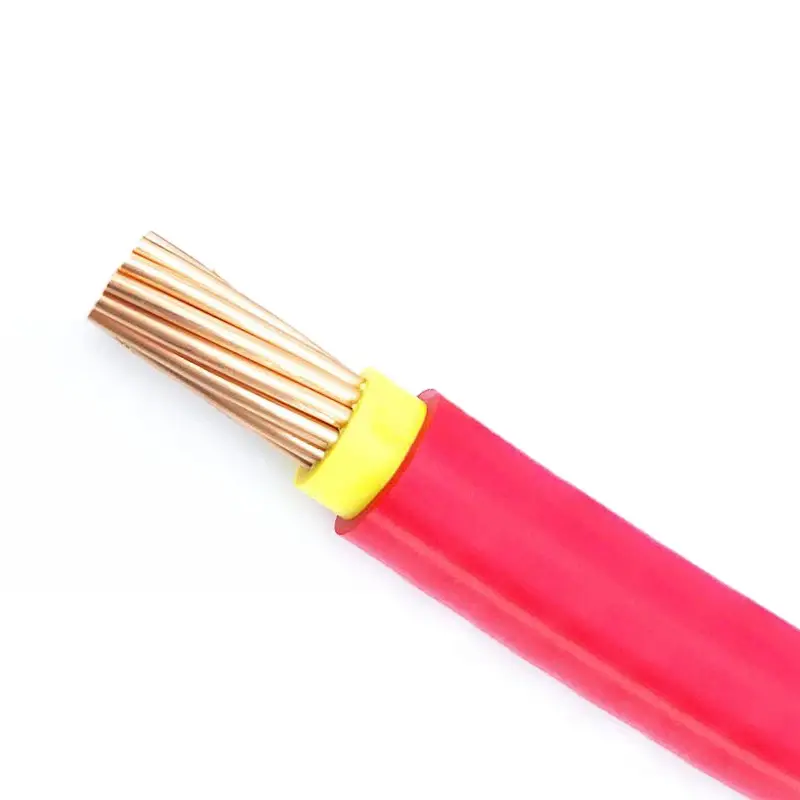

The primary function of insulation in cables is to provide a protective barrier between the conductors and the environment. This protection is vital for preventing electrical and mechanical damage to the conductors, as well as for ensuring the safety of the cable. Without insulation, cables would be vulnerable to moisture, chemicals, and other external factors that could compromise their performance and lifespan.

There are several types of insulation used in cable technology, each with its own set of properties and applications. Some common types of insulation include PVC, XLPE, and rubber. PVC insulation is widely used for its affordability and resistance to moisture, while XLPE insulation is known for its excellent electrical properties and thermal stability. Rubber insulation is often used in applications where flexibility and durability are required, such as in industrial and automotive settings.

The choice of insulation depends on the specific requirements of the cable, such as voltage rating, temperature range, and environmental conditions. It is essential to select the right type of insulation to ensure that the cable can perform reliably and safely in its intended application.

Insulation also has a significant impact on the overall performance of cables. It affects the electrical properties, such as capacitance, resistance, and impedance, which can influence the signal transmission and power efficiency of the cable. Additionally, insulation can affect the thermal and mechanical properties of the cable, impacting its ability to withstand physical stress and temperature variations.

In addition to its technical aspects, insulation also plays a critical role in ensuring the safety of the cable. Proper insulation prevents electrical leakage and reduces the risk of electrical shocks and short circuits. This is particularly important in high-voltage and critical applications, where the consequences of insulation failure can be severe.

In conclusion, insulation is a fundamental component of cable technology, with a vital role in protecting and enhancing the performance of the cables. By understanding the function, types, and impact of insulation in cable technology, engineers and designers can make informed decisions to ensure the reliability and safety of cable systems in various applications.

Insulation cable is a critical element in the design and manufacturing of cables, and it is essential to recognize its significance in ensuring the performance and safety of cable technology. With the continual advancement of cable technology, the importance of insulation will only continue to grow, making it essential for engineers and designers to have a comprehensive understanding of its role and impact.

Types of Insulation Materials Used in Cables

Cables are an essential component of modern technology, used to transmit power and data over long distances. Without proper insulation, cables would be prone to electrical interference, resulting in signal loss, power leakage, and even fire hazards. In this article, we will discuss the various types of insulation materials used in cables and their importance in cable technology.

Insulation in cables serves several crucial purposes. It acts as a barrier to prevent the flow of electrical current between conductors, reducing the risk of electrical shock and fire. Insulation also provides mechanical protection, ensuring that the conductors are shielded from physical damage and environmental factors such as moisture, heat, and chemicals. Additionally, insulation can improve the cable's performance by minimizing signal loss and maintaining the integrity of transmitted data and power.

There are several types of insulation materials used in cables, each with its own unique properties and applications. One common insulating material is polyvinyl chloride (PVC), which is known for its flexibility, resistance to moisture, and low cost. PVC is often used in low-voltage cables for indoor applications, such as household wiring and electronic devices.

Another widely used insulation material is cross-linked polyethylene (XLPE), which offers excellent thermal and chemical resistance, making it suitable for high-voltage and outdoor cables. XLPE insulation is commonly found in power distribution cables, underground cables, and industrial applications where durability and reliability are paramount.

In certain high-performance cables, thermoset materials such as ethylene propylene rubber (EPR) and silicone rubber are utilized for their superior electrical and mechanical properties. EPR is highly resistant to heat, ozone, and weathering, making it an ideal choice for medium-voltage power cables and industrial machinery. Silicone rubber, on the other hand, can withstand extreme temperatures and harsh environments, making it suitable for aerospace, automotive, and medical applications.

For cables that require enhanced fire resistance, materials such as fluoropolymers (e.g., polytetrafluoroethylene or PTFE) and mica tape are used as insulation. PTFE is known for its non-flammability, chemical inertness, and exceptional dielectric properties, making it a popular choice for aerospace, military, and telecommunications cables. Mica tape, combined with a flame-retardant binder, provides outstanding fire resistance and thermal stability, making it indispensable in fire alarm systems, emergency lighting, and critical circuit protection.

In recent years, there has been a growing interest in environmentally friendly insulation materials, such as bio-based polymers and recycled plastics, to reduce the environmental impact of cable production and disposal. These sustainable alternatives offer comparable performance to traditional insulation materials while minimizing the use of fossil fuels and reducing carbon emissions.

In conclusion, insulation is a critical component of cable technology, ensuring the safety, reliability, and performance of electrical and data transmission. The choice of insulation material depends on various factors, including voltage rating, environmental conditions, fire safety requirements, and sustainability goals. By understanding the different types of insulation materials used in cables, manufacturers and engineers can make informed decisions to meet the diverse needs of modern infrastructure and technology.

Benefits of Proper Insulation in Cable Technology

Proper insulation in cable technology is essential for the efficient and safe operation of various electrical systems. Insulation is a critical component of cables, providing protection against environmental factors and ensuring reliable transmission of electrical signals. In this article, we will explore the many benefits of proper insulation in cable technology.

First and foremost, proper insulation in cables helps to prevent electrical leakage and short circuits. Without insulation, the conductive materials within the cable would be susceptible to coming into contact with each other or with external conductive materials, leading to the risk of short circuits. This can result in damage to equipment, fires, and even electrical shocks. By effectively insulating the conductive materials within the cable, these risks are significantly reduced, ensuring the safety of the electrical system.

Furthermore, proper insulation in cables also helps to protect against environmental factors such as moisture, heat, and chemicals. Moisture, in particular, can severely impact the performance and longevity of cables. Without adequate insulation, moisture can seep into the cable, causing corrosion and degradation of the conductive materials. Proper insulation acts as a barrier against moisture, ensuring that the cable remains protected and functional even in challenging environmental conditions.

In addition to protecting against moisture, insulation in cables also helps to maintain the integrity of the electrical signals being transmitted. Without insulation, electrical signals can suffer from interference and loss of conductivity, leading to inefficiencies and potential data loss. Proper insulation ensures that the electrical signals remain intact and are transmitted reliably, ensuring the overall performance of the electrical system.

Proper insulation in cables also plays a crucial role in reducing energy loss. Inadequately insulated cables can result in energy wastage due to resistance and leakage of electrical currents. This not only leads to increased energy costs but also reduces the overall efficiency of the electrical system. Proper insulation minimizes energy loss, allowing for more efficient transmission of electrical signals and reducing the environmental impact of the electrical system.

Furthermore, proper insulation in cables provides mechanical protection, preventing damage from external forces and impacts. Cables are often subjected to various mechanical stresses, such as bending, stretching, and abrasion. Without insulation, the conductive materials within the cable would be vulnerable to these stresses, potentially leading to breakage and failure. Proper insulation helps to reinforce the structural integrity of the cable, ensuring that it can withstand the demands of its environment.

In conclusion, the benefits of proper insulation in cable technology are far-reaching and essential for the efficient and safe operation of electrical systems. Insulation provides protection against electrical leakage, environmental factors, and mechanical stresses, ensuring the reliability and longevity of cables. It is clear that proper insulation is a fundamental aspect of cable technology, one that cannot be overlooked or underestimated. As technology continues to advance, the importance of proper insulation in cable technology will only become more pronounced, highlighting the critical role it plays in the modern world of electrical systems and communications.

Common Issues with Insulation in Cables

Insulation in cable technology is crucial for the proper functioning and safety of electrical systems. The insulation in cables acts as a protective barrier that prevents electrical currents from leaking out and causing potential hazards. However, there are common issues with insulation in cables that can compromise the integrity of the system. In this article, we will explore the importance of insulation in cable technology and discuss the common issues that can arise.

One of the most common issues with insulation in cables is degradation over time. As cables are exposed to environmental factors such as heat, moisture, and chemicals, the insulation can deteriorate, leading to potential electrical faults. This degradation can occur in both organic and inorganic insulation materials, and it is important for cable manufacturers to use materials that are resistant to environmental stressors.

Another common issue with insulation in cables is damage during installation or maintenance. Improper handling or installation of cables can lead to nicks, cuts, or other forms of damage to the insulation, which can compromise the safety and performance of the cable. Additionally, maintenance activities such as cable splicing or repairs can also result in damage to the insulation if not carried out carefully.

Furthermore, inadequate insulation thickness can also be a common issue in cable technology. If the insulation is too thin, it may not be able to withstand the electrical stress and environmental factors, leading to potential short circuits or electrical leakage. It is important for cable manufacturers to ensure that the insulation thickness is sufficient for the intended application.

In addition, manufacturing defects in insulation materials can also pose challenges in cable technology. If the insulation material does not meet the required standards or specifications, it can lead to premature failure or performance issues in the cable. It is essential for manufacturers to conduct rigorous testing and quality control measures to ensure the reliability of the insulation materials.

Moreover, the presence of contaminants in the insulation material can also be a common issue in cable technology. Contaminants such as moisture, dirt, or other foreign particles can reduce the insulation resistance and lead to electrical breakdown. Proper handling and storage of insulation materials are essential to prevent contamination and ensure the integrity of the cable insulation.

To mitigate these common issues with insulation in cables, it is important for cable manufacturers to use high-quality insulation materials that are designed to withstand environmental stressors and electrical loads. Additionally, proper installation and maintenance practices are crucial to prevent damage to the insulation and ensure the safety and reliability of the electrical system.

In conclusion, the insulation in cable technology plays a critical role in protecting electrical systems and ensuring their safe and reliable operation. However, there are common issues with insulation in cables that can compromise the integrity of the system. By addressing these issues and implementing proper quality control measures, manufacturers can ensure the effectiveness of cable insulation and enhance the overall performance of electrical systems.

Advancements in Insulation Technology for Cables

In the world of cable technology, insulation plays a crucial role in ensuring the safety and efficiency of electrical systems. Advancements in insulation technology for cables have revolutionized the way we use and maintain electrical systems, leading to improved performance and increased safety. In this article, we will explore the importance of insulation in cable technology and the recent advancements that have been made in this field.

Insulation in cables serves to protect the conductors from environmental factors such as moisture, heat, and mechanical stress, as well as to prevent electrical leakage and short circuits. Without proper insulation, cables are susceptible to damage and can pose serious safety hazards. As such, advancements in insulation technology have been a key area of focus for researchers and engineers in the field of cable technology.

One of the most significant advancements in insulation technology for cables is the development of materials with enhanced thermal and electrical properties. Traditional insulation materials such as PVC and rubber have limitations in terms of their ability to withstand high temperatures and voltages. However, recent developments in polymer science and nanotechnology have led to the creation of new insulation materials with superior thermal and electrical performance.

For example, nanocomposite insulation materials, which consist of nano-sized particles dispersed in a polymer matrix, have shown great promise in enhancing the thermal stability and electrical breakdown strength of cables. These materials have the potential to enable the use of higher operating temperatures and voltages, thus increasing the capacity and efficiency of electrical systems.

In addition to improved thermal and electrical properties, advancements in insulation technology have also focused on environmental sustainability. With the increasing emphasis on green technologies, there has been a growing demand for insulation materials that are environmentally friendly and non-toxic. As a result, researchers have been working on developing bio-based and biodegradable insulation materials derived from renewable sources such as plant oils and biomass.

Furthermore, the development of self-healing insulation materials has been a significant breakthrough in addressing the issue of cable maintenance and repair. Self-healing materials have the ability to autonomously repair small damages or punctures, thereby extending the service life of cables and reducing the need for frequent maintenance and replacement.

Advancements in insulation technology have not only improved the performance and safety of cables, but have also contributed to cost savings and enhanced reliability in electrical systems. These developments have paved the way for the adoption of advanced insulation materials in a wide range of applications, including power transmission and distribution, automotive, aerospace, and telecommunications.

In conclusion, insulation plays a critical role in cable technology, and recent advancements in insulation technology have had a profound impact on the safety, performance, and sustainability of electrical systems. The development of new materials with superior thermal and electrical properties, as well as the focus on environmental sustainability and self-healing capabilities, have set the stage for a new era of innovation in cable insulation. As the demand for more efficient and reliable electrical systems continues to grow, the importance of insulation in cable technology will only become more pronounced.

Conclusion

In conclusion, the importance of insulation in cable technology cannot be overstated. Insulation plays a crucial role in maintaining the integrity and efficiency of cables, protecting them from environmental factors, and ensuring reliability in various applications. Whether it is for power transmission, telecommunications, or data transfer, proper insulation is essential for the overall performance and longevity of cables. As technology continues to advance and demand for high-speed, high-capacity data transmission grows, the significance of insulation in cable technology becomes even more critical. It is clear that investing in high-quality insulation is a wise decision for businesses and industries looking to maximize the potential of their cable systems. In the end, the success and reliability of cable technology rest heavily on the quality of its insulation.